The Fan Energy Index changes how we think about fans

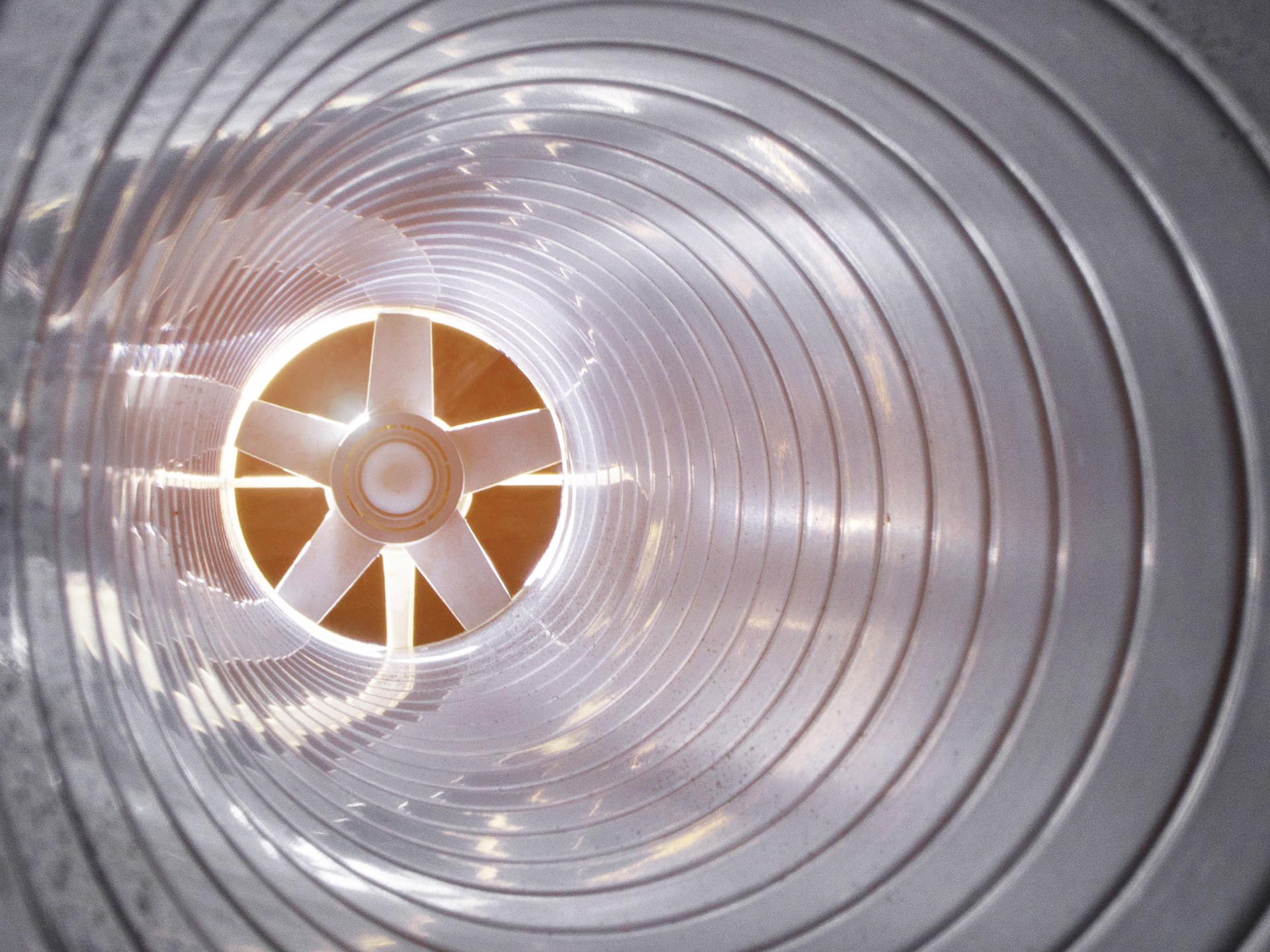

Fans are everywhere in our buildings, but they mostly exist so we don’t have to think about them. When working properly, fans become the white noise of indoor spaces; we only tend to notice them when we’re uncomfortable.

Perhaps because we tend to ignore them, fans have historically felt a cool reception when it comes to energy efficiency. In much of our research on high-performance buildings, we evaluate new, exciting gizmos and concepts to determine their potential energy savings. When it comes to fans, however, the technology hasn’t really changed. Motor, blades, rotation – that’s pretty much it. Technologies such as variable frequency drives do achieve some energy savings, but surely there are opportunities for fans to do better.

As it turns out, there are. Recently, the savings potential of standalone fans has heated up thanks to a new method in which we choose the proper fan to use in a situation. As with other performance-based measures, we can achieve energy savings by setting a specific efficiency goal based on the building’s unique conditions. Once we know exactly what a fan needs to accomplish, we can select the best fan to meet that target.

Meet the Fan Energy Index

The improvement comes in the form of the Fan Energy Index (or FEI), a metric first developed by the Air Movement and Control Association. Under the new metric, a fan manufacturer provides a matrix of various FEI numbers, each based on a combination of factors such as pressure (PSI) and flow rate (CFM). Some fans might excel in low-pressure, high-flow situations, but that doesn’t mean they’ll work as efficiently under high pressure. The Fan Energy Index tells you the situations in which a fan might excel and, likewise, when a different fan might be a better choice.

Conversely, under the most common existing metric, known as the Fan Efficiency Grade (or FEG), a designer might select a fan based on a set efficiency metric at a condition that may not apply. For example, let’s say a designer chooses a fan based on its standard FEG, which says it is 92 percent efficient. However, when applied to the actual conditions of the building, the fan only operates at 80 percent efficiency.

The Fan Energy Index seeks to correct this problem by tackling the problem in reverse. Under FEI, a designer looks at the application intended for the fan and, based on the pressure and flow rate, selects a fan with a FEI that meets those specific conditions. This time, the fan does indeed operate at 92 percent efficiency – all because we selected the fan based on the building’s specific needs.

What’s next for the Fan Energy Index?

Eventually, the Fan Energy Index will find its way into building codes. At Slipstream, we partnered with the ComEd Energy Efficiency Program to determine how FEI could be deployed sooner, more broadly, and to greater effect than code would. We evaluated the market readiness of the Fan Energy Index and determined the applications in which it can make the biggest impact in energy efficiency programs. Combining our technical experience with data analysis, we set out to provide practical guidance around FEI implementation to help developers, designers, and utilities put the FEI into practice.

From our research, it’s clear that the FEI has significant energy savings across many applications. In general, the potential savings is approximately 53 and 26 million kWh annually for the commercial and industrial sectors, respectively. We also found several factors that could inform program design, including:

- The normalized savings are larger in the industrial sector, where fans operate at higher speeds and longer hours.

- The savings are also higher in smaller fans, which tend to be less efficient.

- Within the commercial sector, hours of operation is a key function of FEI energy savings. Building types with longer hours of fan operation—such as multifamily buildings, hospitals, and hotels—see greater savings than warehouses or schools.

- The energy savings are higher in retrofits than new construction. However, the costs of a retrofit are much higher, as you’d have to factor in the full costs of replacement and reinstallation.

- Fans are reliable equipment that can last for 20 years, so we rarely think about replacing them. A program should include education and training to raise awareness of FEI and the potential savings of retrofits.

As a result of this study and the conclusions above, the project team recommended a midstream incentive to drive market adoption of the FEI metric.

Request a copy of the full report.

For our part, we feel it’s important to educate building operators, facility managers, and designers on the big changes that will soon be blowing their way.

Read more about optimizing building performance with HVAC, VRF systems, and more.